Optimised endmill for highly alloyed steels offers end users an edge in the market

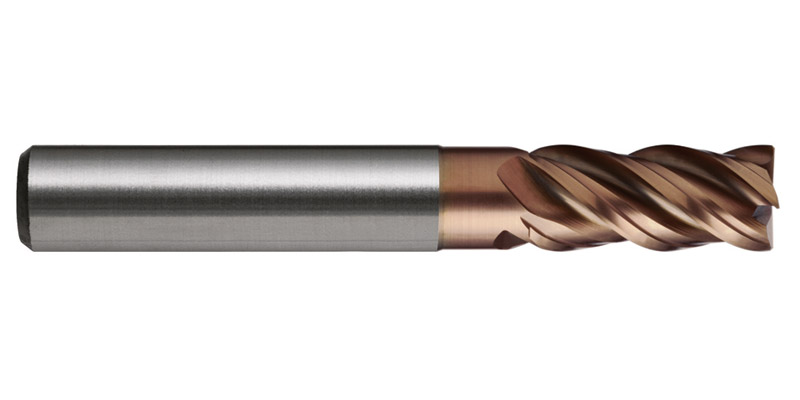

Sutton Tools has launched the latest addition to complement its Harmony family of endmills. The new VA-Harmony EndMill has been engineered specifically for milling stainless steels and super alloys—such as austenitic grades 304 and 316, duplex grades, as well as inconels 718 and 725.

Available in diameters from 6mm to 20mm, the VA-Harmony Endmill is ideal for a range of milling operations, including finishing, side cutting, oblique cuts, roughing and slotting, all with the one tool!

The VA-Harmony Endmill has been engineered to deliver optimised performance. The design incorporates an ultra-fine micro grain carbide base material, combined with the Balzers Oerlikon Helica multi-layer coating. Together with the 40/42-degree unequal flute helix and the 45-degree corner chamfering edge-protection, the VA-Harmony Endmill outperforms competing endmills in both bench testing and end-user assessments.

The VA-Harmony Endmill delivers a winning combination of quality performance and longer tool life to component manufacturers for the oil & gas, aerospace, food & beverage, medical and marine industries.

The VA-Harmony Endmill is a versatile tool that offers an industry-leading performance—suppressing chatter, and facilitating higher feed-rates, longer tool-life and increased productivity compared with conventional endmills. The VA-Harmony Endmill will give you an outstanding edge in the market.

Sutton Tool’s latest product breakthrough is its VA-Harmony EndMill, which has been engineered specifically for milling stainless steels and super alloys—such as austenitic grades 304 and 316, duplex grades, as well as inconels 718 and 725.

The edge-preparation design of the VA-Harmony Endmill incorporates 45-degree corner chamfering edge-protection to provide additional strength to the endmill.

Productivity is further enhanced by the inherent ability of the VA-Harmony Endmill to be used for a number of milling operations—including finishing, side cutting, oblique cuts, roughing and slotting.

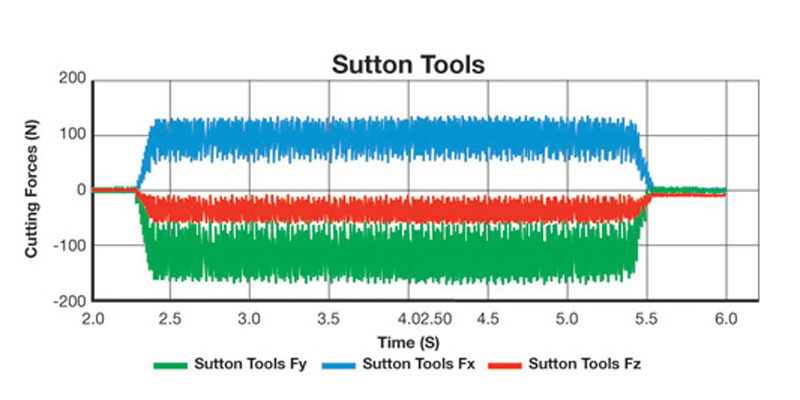

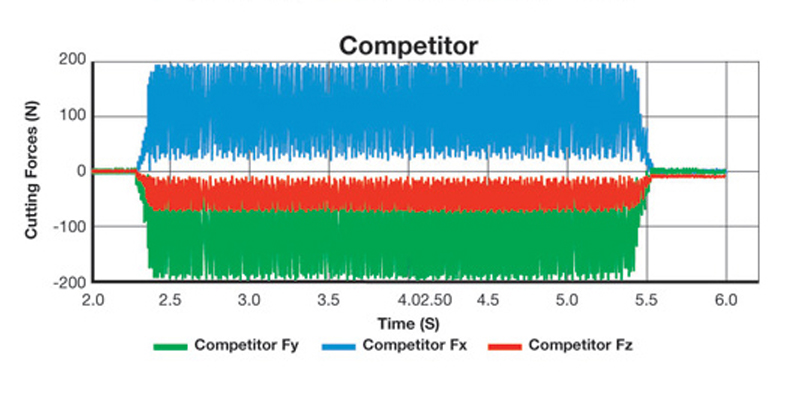

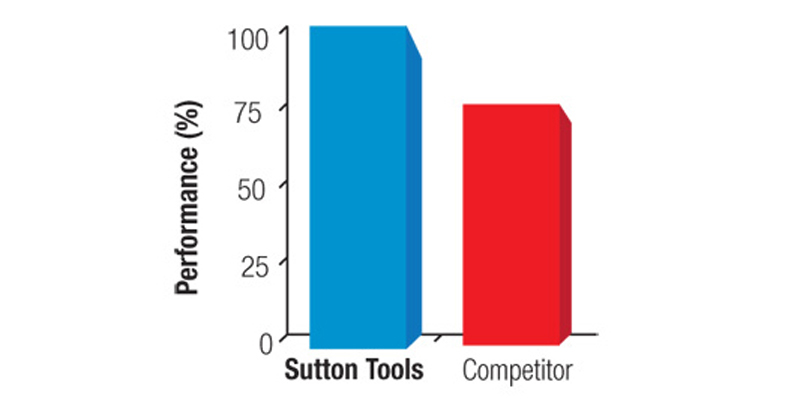

The VA-Harmony Endmill consistently outperforms leading brands currently on the market when analysed under identical operating conditions: cutting forces are significantly lower in the X-, Y- and Z-axes, and this is indicative of lower tool wear and longer tool life.